Practical advice

- Remove the battery from the power tool before carrying out work on the power tool (e.g. maintenance, changing tool, etc.). The battery should also be removed for transport and storage. There is risk of injury from unintentionally pressing the on/off switch.

The parking rest (32) makes it possible to put down the power tool directly after working, without any danger of damaging the workpiece or planer blade. During the work process, the parking rest (32) is highly pivoted and the rear section of the planer base plate (11) is released.

Note: The parking rest (32) must not be removed.

Set the required cutting depth and position the power tool with the front section of the planer base plate (11) on the workpiece.

- Only bring the power tool into contact with the workpiece when switched on. Otherwise there is danger of kickback if the cutting tool jams in the workpiece.

Switch on the power tool and guide it over the surface of the workpiece, applying uniform feed.

To achieve high-quality surfaces, apply only a low feed rate and exert pressure on the middle of the planer base plate.

For the processing of hard materials, such as hardwood, and also when utilising the maximum planing width, set only a low cutting depth and reduce the planer feed as appropriate.

Excessive feed reduces the quality of the surface finish and can lead to the chip ejector quickly becoming blocked.

Only sharp planer blades achieve good cutting performance and make the power tool last longer.

The integrated parking rest (32) also enables a continuation of the planing procedure following interruption at any point on the workpiece:

- Place the power tool – with parking rest folded down – onto the area of the workpiece that you will continue to work on.

- Switch the power tool on.

- Shift the contact pressure onto the front of the planer base plate and slowly slide the power tool forward (➊). In doing so, the parking rest will swivel upwards and out of the way (➋), meaning that the rear section of the planer base plate is in contact with the workpiece again.

- Guide the power tool over the surface of the workpiece, applying uniform feed (➌).

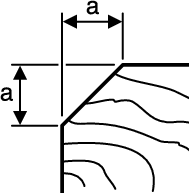

The V-grooves in the front of the planer base plate enable quick and easy chamfering of workpiece edges. Select the V-groove that corresponds to your chamfering width. Then position the planer with the V-groove onto the edge of the workpiece and guide it along.

| Groove used | Dimension a (mm) |

None | 0–2.5 | |

Small | 1.5–4.0 | |

Medium | 2.0–4.5 | |

Large | 3.0–5.5 |

Fit the parallel guide (24) to the power tool using the fastening screw (27). Depending on the application, attach the rebate depth guide (31) to the power tool with the fastening screw (30).

Loosen the locking nut (26) and set the desired rebate width on the scale (25). Retighten the locking nut (26).

Set the desired rebate depth accordingly using the rebate depth guide (31).

Carry out the planing procedure several times until the desired rebate depth has been achieved. Guide the planer with sideways contact pressure.